BAUMANN toolbox

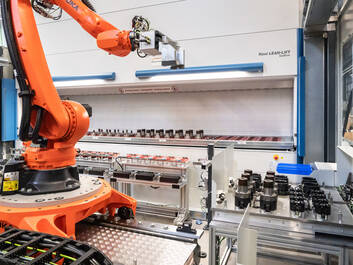

FULLY AUTOMATED TOOL PREPARATION

In many manufacturing companies, loading and unloading of shrinking and measuring devices, storing and retrieving tools, as well as feeding tool assemblies to the machine are still done manually.

This approach is labor-intensive, leads to high operating costs, and complicates planning. In addition, personnel-related risks of downtime, quality fluctuations, and the increasing shortage of skilled workers pose further challenges to stable production processes.

Automated tool handling can significantly increase productivity, reduce errors, and sustainably lower costs.

Lower operating costs due to reduced personnel requirements

Elimination of quality fluctuations caused by manual intervention

No misplacements or incomplete documentation

Reduced number of tools through centralized coordination

Less effort in personnel coordination and shift planning

Increased resilience to the shortage of skilled workers

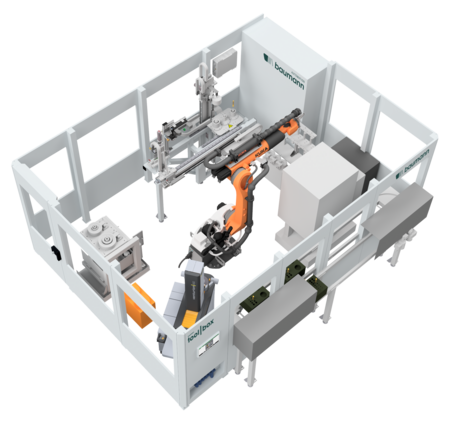

TOOL|BOX 300 BASIC

Configuration Example tool|box 300 Basic

- Up to 300 tool changes per day

- HSK holders: HSK63, HSK100

- Tool Identification: RFID or DMC

- Expandable with storage lifts for the storage of tools, fixtures, and tool assemblies

Can be adapted to customer-specific requirements (e.g. number of tool changes, range of HSK sizes, etc.) as well as specific local conditions.

1. Workpiece carrier for manual loading and unloading of tools and HSK holders

2.

Shrinking station

3.

Cooling station

4.

Measuring machine

5. Cleaning system (spray cleaning with filter and oil separator)

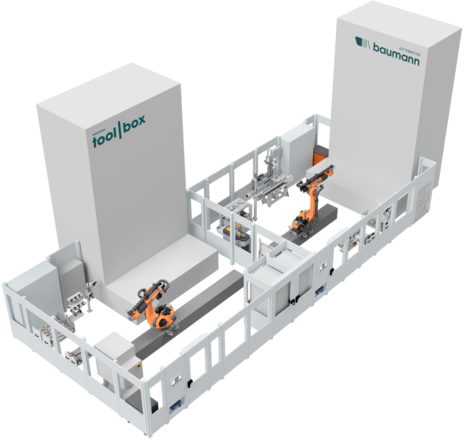

TOOL|BOX 300

Configuration Example tool|box 300

Up to 300 tool changes per day

HSK holders: HSK63, HSK100

Storage locations for tools: 6,000

Storage locations for holders: 1,000

Storage locations for tool assemblies: 1,300

Access points for 2 transport trolleys

Database management

Tool life management

Interface to tool planning

Can be adapted to customer-specific requirements (e.g. number of tool changes, range of HSK sizes, etc.) as well as specific local conditions.

1.

Drawers for manual loading and unloading of tools and HSK holders

2.

DMC reading station for identification of HSK holders and tool measurement

3.

Storage lift for storing tools and HSK holders

4.

Shrinking station

5.

Cooling station

6.

Measuring machine

7.

Transfer shuttle between Cell 1 and Cell 2

8.

Storage lift for storing tool assemblies

9.

Cleaning system (spray cleaning with filter and oil separator)

10.

Drawer for manual loading of non-shrunk tool assemblies

11.

Removal and supply of new and used tool assemblies on transport trolleys

12.

Reserved spaces for connecting driverless transport systems

Options

Scaling to individual number of tool changes per day

Integration of additional HSK sizes

Adjustment of storage capacity for holders, tools, and tool assemblies

Application-specific cleaning system

Additional access points for further transport trolleys

Integration of manual workstations for indexable insert changes

Integration of driverless transport systems as an alternative to transport trolleys

Integration of a gantry portal for transferring e.g. heavy-duty tools

Integration of existing equipment (e.g. existing measuring machine, storage lifts)

Interface to the ERP system

Database management of shrinking parameters

Layout adaptation to local conditions